Rigging and lifting operations happen frequently on construction sites. Whether you are a seasoned rigger or just working nearby, understanding the risks and responsibilities can prevent injuries and even save lives. Riggers are responsible for choosing, inspecting, and setting up rigging safely. Everyone else nearby needs to stay aware, stay clear, and know what to do (and what not to do) around lifting activities.

Dangers of Poor Rigging

- Dropped loads can crush and seriously injure people, equipment, and property

- A damaged sling or unbalanced load can fail without warning

- Workers standing under or too close to a load can be hit if something goes wrong

Basic Rigging Rules

- Only trained and authorized personnel should rig or signal a crane. If the crane company has their own riggers and signalers onsite, they should be the ones performing that work and communicating with the crane operator.

- Never stand under a suspended load.

- Use taglines to guide and control the load when needed – never your hands.

- Communicate clearly with the crane operator. Use hands signals or radios and have a designated signal person. The pick plan should also be discussed with everyone involved in the pick.

- Check the load path. Tape off and make sure no one is in the fall zone before lifting.

- Know your rigging limits – weight of the load, sling angles, and hardware ratings all matter.

Inspecting Rigging Equipment

Damaged, old, dirty, or UV damaged rigging equipment must not be used. Inspecting this equipment before every lift is a requirement. Here’s what to look for:

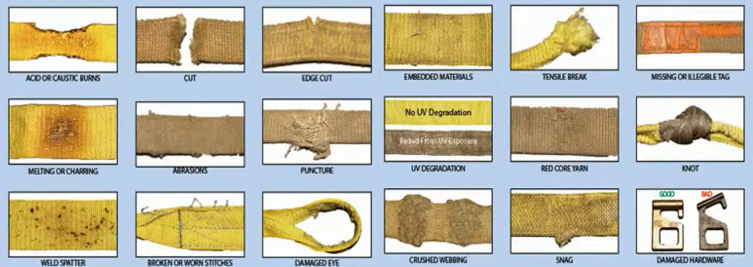

- Web Slings – cuts, tears, fraying, burns, melted fibers, acid damage, chemical damage, discoloration, stiffness, worn or missing tags.

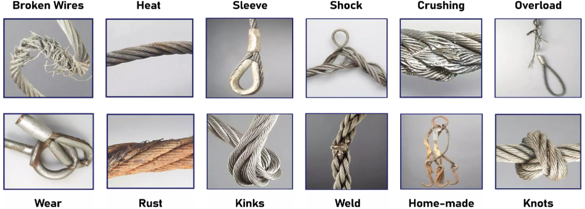

- Wire Rope Slings – broken wires, kinks/crushing, rust, corrosion, bird-caging, damaged end fittings, damaged hooks, worn or missing tags.

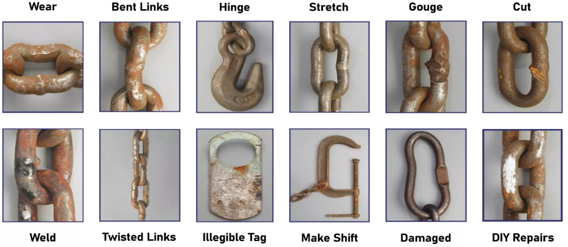

- Chain Slings – bent or stretched links, nicks, gouges, heat damage, hooks that don’t close on their own or have bent latches, worn or missing tags.

Another thing to take note of, if any of your rigging equipment does not have a tag with the manufacturer and load limits on it… it is useless and should be taken out of service.

Even if you are not the one inspecting rigging equipment and rigging loads, being aware of what proper rigging equipment should look like can help keep you and your coworkers safe. When rigging equipment gets worn, cut, old, UV damaged, or dirty the amount of weight it can hold decreases drastically. If you see something that looks like it is “on its last leg” and should not be used anymore, please say something.

Here are some pictures of what to look for when inspecting rigging slings, chains, and wire ropes.

Stay Safe!